3M Products & Supplies

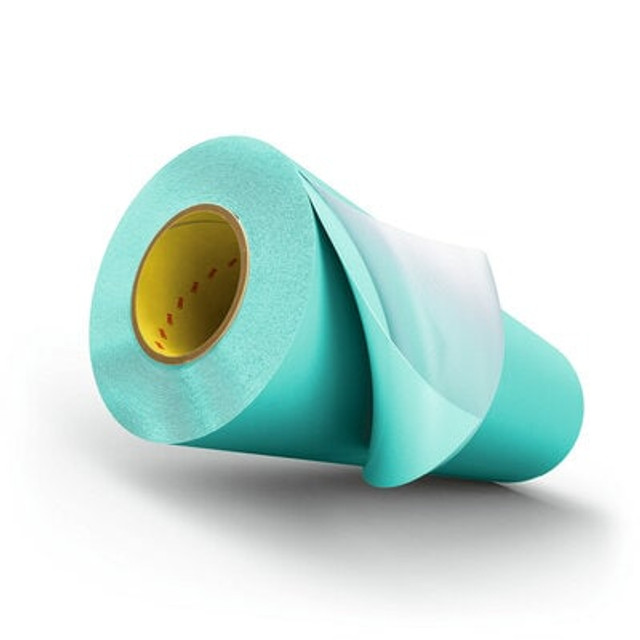

3M Cushion-Mount Plus Plate Mounting Tape E1720H, Teal, 18 in x 25 yd, 20 mil, 1 Roll/Case

Bubble Free Flexographic Plate Mounting

An air release feature with plate side adhesive technology allows 3M Cushion-Mount Plus Plate Mounting Tape L1720 to remove with less force in the presence of ink contaminates on flexographic print plates. This 0.020 inch (0.51 mm) double coated medium firm density teal foam tape is ideal for printing combinations of solids and process with halftone dots and securely bonds the flexographic photopolymer plate to the print sleeve or steel cylinder to prevent plate edge lifting during printing. Notably, this flexographic plate mounting tape has excellent resistance to lifting on press and is tolerant to ink contaminates, allowing for easy and clean plate removal.

Recommended Applications

3M Cushion-Mount Plus Plate Mounting Tape L1720 is constructed with engineered acrylic adhesives for 20 mil applications. The adhesive on the linered (plate) side of the tape is designed for mounting photopolymer plates. Easy plate removal from tape may result in less worker fatigue and plate damage. The adhesive on the non-linered (sleeve/cylinder) side is designed for mounting to flexographic printing cylinders or sleeves, providing easy application at mounting and clean removal when demounting.

On Easy with Reduced Air Entrapment

Unlike flat or pebbled liners, E-Series liners are crosshatched. This imprints unique microchannels into the adhesive that allow air to flow throughout the adhesive. Air bubbles disappear from between the tape and plate, and between the tape and cylinder or sleeve for virtually bubble-free mounting. Setup is faster with smoother surfaces for cleaner print quality and higher productivity. The adhesive maintains tight contact with reduced edge lifting.

Understanding Flexographic Plate Mounting Tapes

3M flexographic plate mounting tapes are highly engineered to provide very tight caliper tolerance to allow flexographic printers to use tape from different manufacturing lots and keep tight print registration. The compressible foam will withstand long and high speed print runs.

Keep the Presses Running and your Customers Coming Back

For decades, 3M products have been at work in paper mills and printing plants helping to improve the quality of the work that goes out and the efficiency of how it gets done. From paper web splicing to plate mounting and packaging the finished job, you can rely on 3M for solutions and service throughout your operation.

Click here for more information on Flexographic Mounting Systems